Welding Capacity

Automated Welding Technology

• Process Range: Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Submerged Arc Welding (SAW)

• Pipe Diameter Coverage: From ultra-small DN25mm to ultra-large 3m, adaptable to complex industrial scenarios

• Production Capacity: Annual output of 300 sets of liquid ring vacuum/compressor systems and complete welded assemblies

Special Materials Welding

• Material Types: Carbon steel, stainless steel, super duplex stainless steel, titanium alloys, etc.

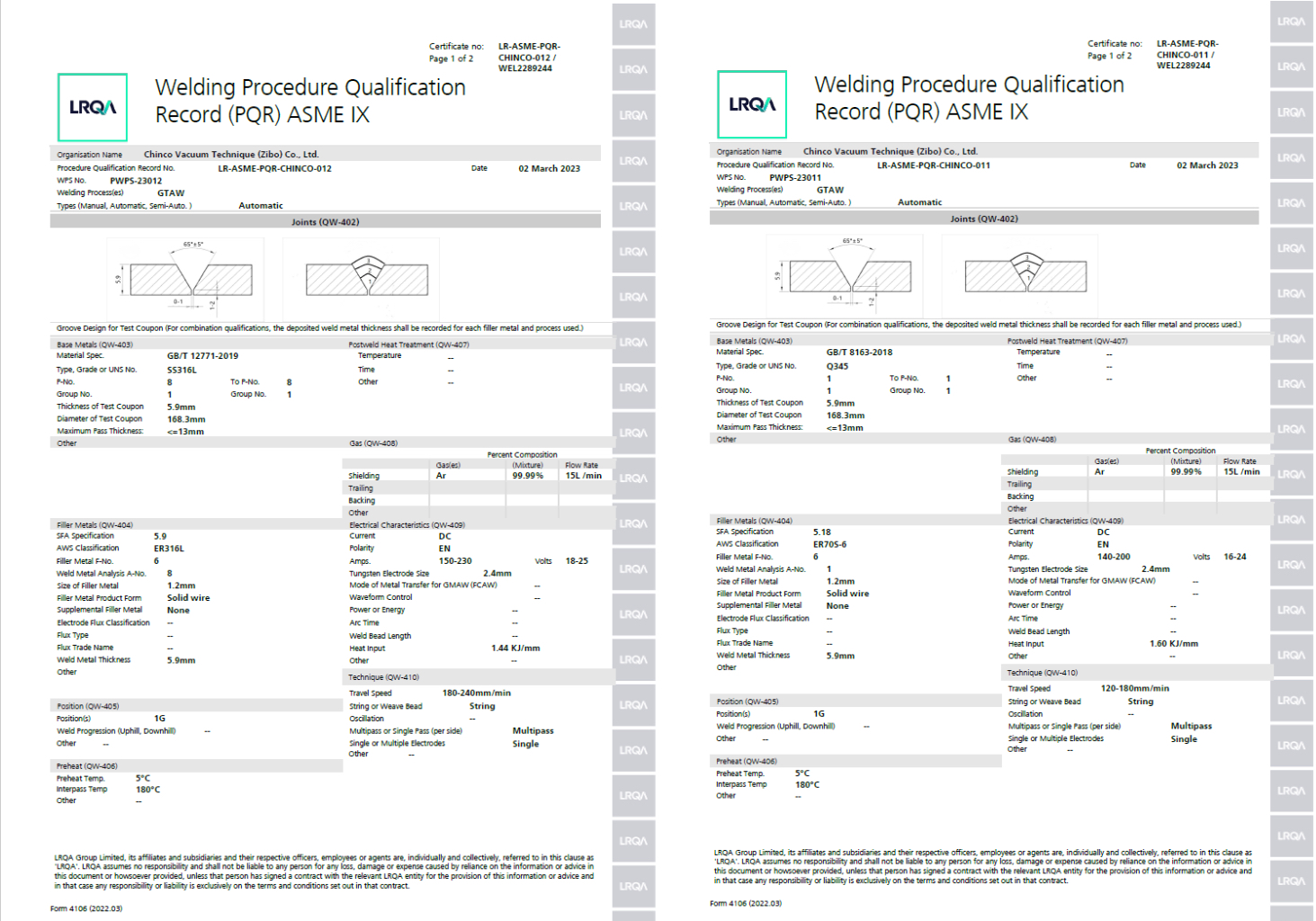

• Standard Compliance: Welding procedures and welder qualifications strictly follow ASME and GB standards

• Quality Assurance: Every weld undergoes reliability testing to ensure performance compliance

International Engineering Team

• Technical Support: Two International Welding Engineers (IWE) oversee the entire welding process and quality control

• High-End Adaptability: Meets the demanding welding requirements of petrochemical, energy equipment, and other industries

Professional Surface Treatment

• Equipment Setup: High-efficiency shot blasting system

• Standard Execution: Achieves Sa2.5-grade cleanliness and roughness requirements

• Process Integration: Enhances subsequent coating and anti-corrosion performance, extending component lifespan

The copyright of the above images belongs to CHINCO Vacuum Technology (Zibo) Co., Ltd. Any unit or individual is not allowed to steal them without permission.