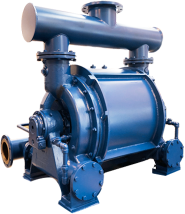

The inlet and outlet of the pump are designed on the planar end face (flat disc), with a maximum pressure of up to 3.3 Kpa, and the suction and discharge volume ranges from 27 to 62,400 m3/h. It includes 2BV series, 2BE1 series, 2BE3 series, SK/2SK series, and DLV series. It is widely used in industries such as chemical engineering, pharmaceuticals, papermaking, food, mining, power, steel, coal, environmental protection, aerospace, etc.

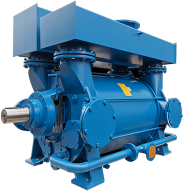

The vacuum pump's suction and exhaust use a conical distributor structure. The cross-sectional area of the suction and exhaust channels is large, and the flow resistance is small, making it more energy-efficient when removing dry air and saturated water vapor. Moreover, the two ends of the impeller are sealed and have good rigidity. The CL series conical liquid ring vacuum pump is often used in applications such as filtration, solvent recovery, desulfurization, vacuum distillation under reduced pressure, dehumidification, condenser vacuum pumping, and water diversion.

The maximum exhaust pressure is 0.15 MPaG. It has a large volume, a simple structure, is easy to maintain, and operates reliably. It can suck flammable and explosive gases and is widely used in the chemical and petroleum industries for polyethylene, styrene, oxides, vinyl chloride monomer, sulfur dioxide, hydrogen sulfide, benzene, butene, oxygen, etc.

Single-stage exhaust pressure is 0.3 MPaG, and double-stage exhaust pressure is 0.8 MPaG. It has double-end face mechanical seals and can compress flammable and explosive gases. It is widely used in the chemical and petroleum industries for polyethylene, styrene, oxides, vinyl chloride monomer, sulfur dioxide, hydrogen sulfide, benzene, butene, oxygen, etc.

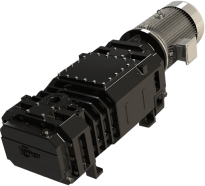

Dry vacuum pumps do not require oil, water or other liquids as media during operation and can achieve relatively clean vacuum. Our main products include reciprocating vacuum pumps, Roots vacuum pumps, air-cooled Roots vacuum pumps, and screw pumps.

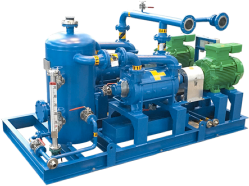

During the company's more than 20 years of vacuum application exploration, it has accumulated rich experience in the application of complete sets of equipment. Our carefully designed vacuum systems can meet demanding application requirements and help reduce installation and operation costs. Whether it is a general liquid ring vacuum system, power industry complete vacuum equipment, or chemical industry composite systems, we have complete solutions.