Power Industry

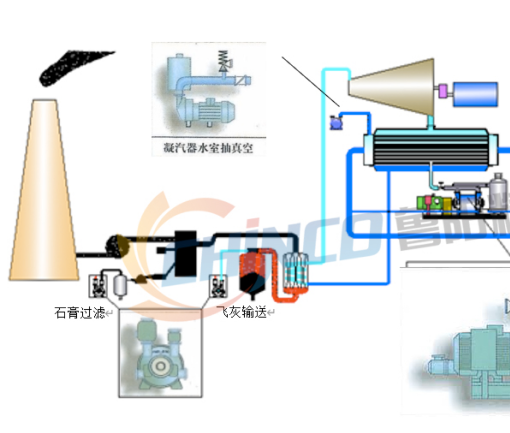

The main applications of vacuum pumps in the power industry include: vacuuming of condensers, vacuum water absorption, flue gas desulfurization, ash transportation, exhaust of turbine sealing pipes, vacuum exhaust, and discharge of geothermal gas, etc.

Condenser Vacuum Pumping

During the vacuum extraction stage, the initial vacuum extraction is carried out in the condenser before steam is introduced. This removes the air and other non-condensable gases within the condenser. In the vacuum maintenance stage, the vacuum pump continues to operate to extract the leaked dry air, maintaining the back pressure of the condenser at the operating point, ensuring the high efficiency operation of the turbine, and improving the thermal efficiency of the power plant.

Vacuum Suction

By using a water ring vacuum pump, a siphon pipe is maintained in the cooling water system of the power generation equipment at all times, enabling the cooling water circulation pump to operate at the designed flow rate and reducing power consumption.

Flue Gas Desulfurization

When desulfurizing the flue gas, gypsum slurry will be produced. It is necessary to use a vacuum belt filter for dehydration. The liquid ring vacuum pump can operate effectively under this condition and perform well.

Fly Ash Transportation

In a vacuum environment, the fly ash is conveyed from the dust collector funnel to the central drying collection point using a fluid transportation method. The liquid ring pump has the ability to withstand the entry of dust into the pump and is an extremely suitable transportation device.

Turbine Seal Pipe Exhaust

The steam turbine uses sealed tubes to seal the shaft, preventing air leakage. These sealing tubes are sealed with steam. A vacuum pump must be continuously used to remove excess steam and condensate.

Vacuum Exhaust, Discharge Geothermal Gas

Before the boiler water enters the system, it must undergo an exhaust process. The geothermal gas is expelled, including the air and other non-condensable gases that are discharged from the steam space of the condenser.

The copyright of the above images belongs to CHINCO Vacuum Technology (Zibo) Co., Ltd. Any unit or individual is not allowed to steal them without permission.